Portfolio

This portfolio provides a non-exhaustive list of selected recent project highlights. In places specific details may remain undisclosed until later publication in full in either publication or patent form. I am always happy to discuss with interested parties.

Redox Flow Iontophoresis for Brain Cancer Therapy

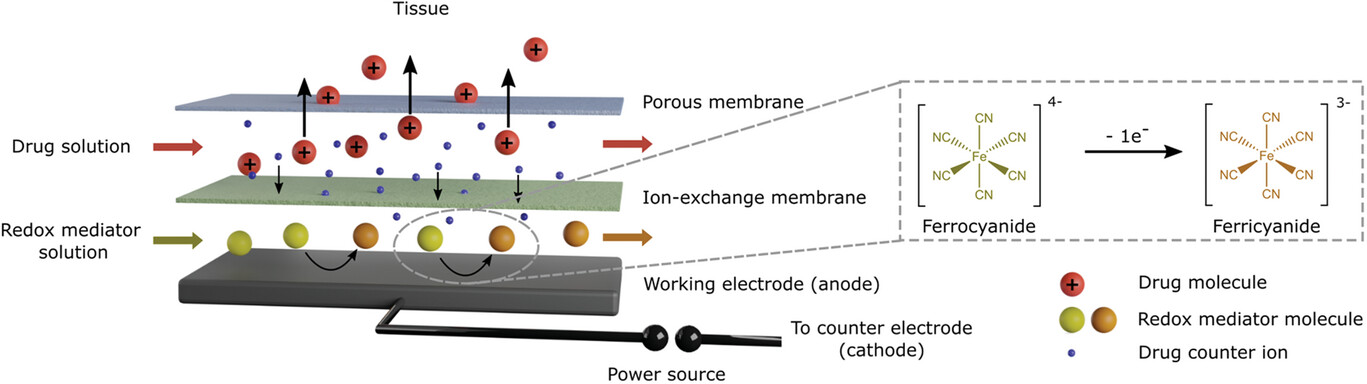

Illustration of the redox flow iontophoresis concept, Adv. Mater. Technol. 9, 2024

Drug delivery to the brain and spinal cord is limited by the blood-brain barrier, which is a major reason for the poor prognosis of brain tumours. Iontophoretic delivery, which uses electrical fields to transport charged drug molecules through an implanted device, offers a promising solution by enabling controlled, pressure-free delivery of large amounts of drug. However, this method is challenged by low performance and poor biocompatibility due to unwanted electrochemical reactions.

Drug delivery out of the device towards a counter electrode on the right.

I have independently developed a new patented device technology called redox flow iontophoresis, which uses a redox mediator molecule and ion-exchange membranes for effective charge transfer. This technique overcomes existing problems with iontophoresis and allows safe, high rate drug delivery into the brain for a theoretically unlimited duration. I have developed a sophisticated system of microfluidic flow controllers, flow sensors, microfluidic valves and a source measurement unit from different manufacturers through which the device is operated. Through the implementation of a intuitive yet powerful graphical user interface (using Python), I have enabled the use of this complex system by those without programming experience i.e. end user medical professionals. The GUI is not yet public, but two of the Python hardware drivers are available on Github and Pypi which I developed for this project.

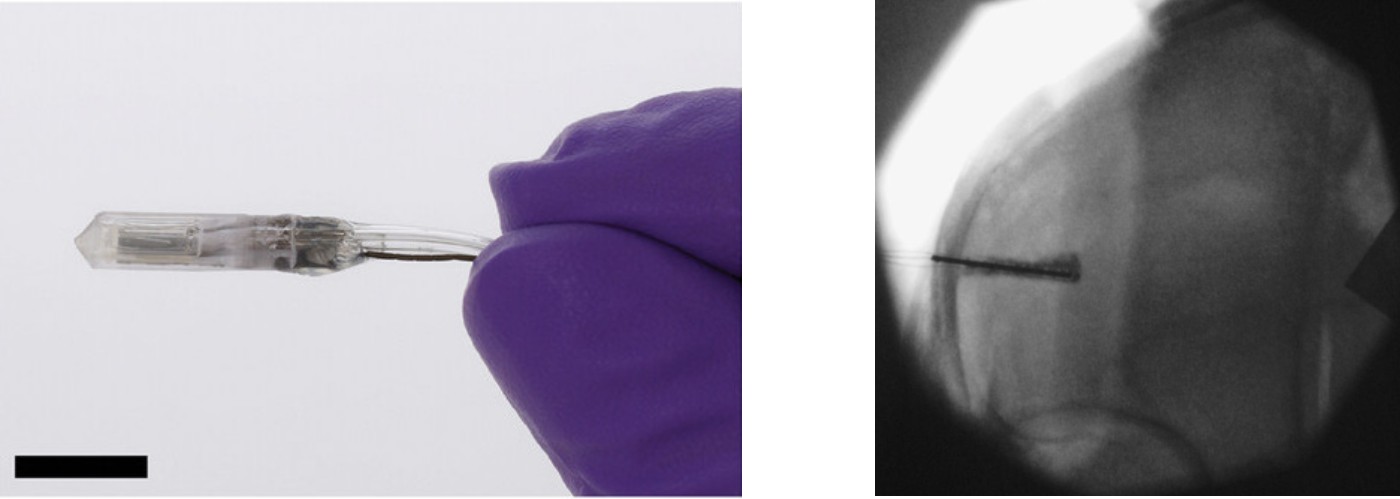

Left: Drug delivery device prototype fabricated by additive manufacturing, parylene C deposition and lamination of freestanding membranes. Scale bar: 1 cm. Right: X-ray of a human cadaveric brain during delivery of a radio contrast agent using my device.

I have designed and fabricated a prototype medical device using additive manufacturing and established an in vivo murine model for efficacy testing. I am currently working on clinical translation by conducting in vivo validation, with the aim of offering the device to canine cancer patients soon.

The technical paper can be found here and the patent can be found here.

Microelectrode and OECT Devices for Neural Recording

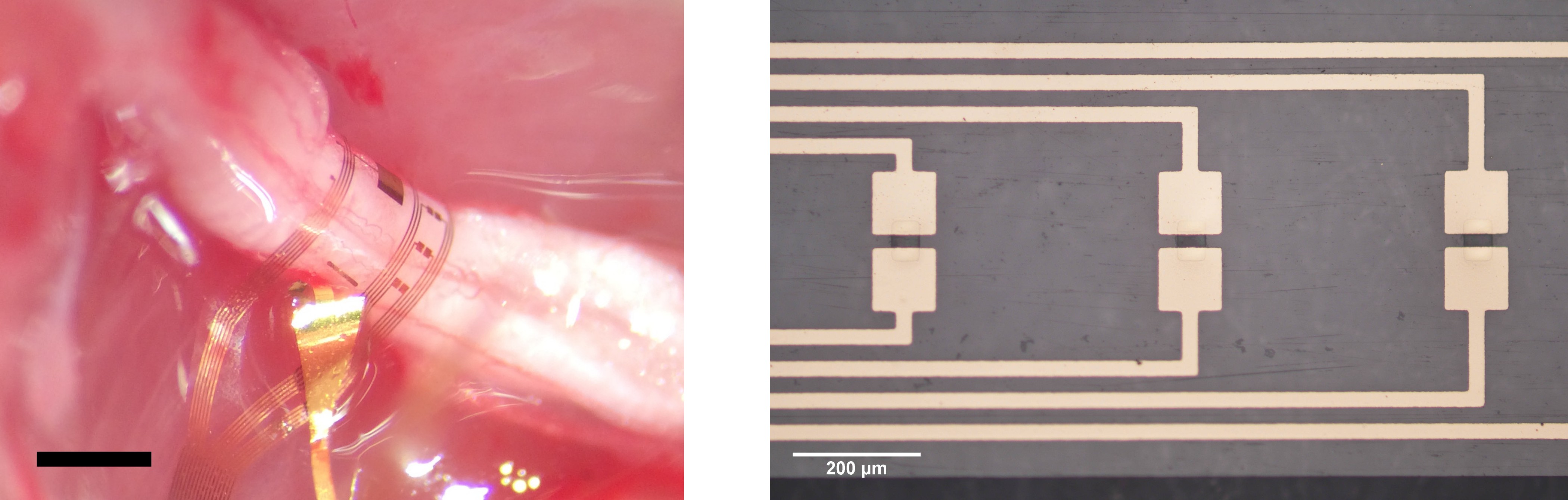

Left: Flexible polymeric implant with microelectrode and OECT arrays wrapped around the sciatic nerve. Scale bar: 1 cm. Right: OECTs on the flexible implant.

I have developed ultrathin, flexible microelectrode and organic electrochemical transistor (OECT) arrays for neural recording. These advanced technologies have the potential to form the next generation of brain-computer interfaces and improve the lives of patients suffering from traumatic nerve injury. I have fabricated the devices in a clean room environment using thin film microfabrication techniques such as photolithography and reactive ion etching. I have also designed and developed printed circuit boards (PCBs) and flexible cables to interface with the devices, enabling efficient data processing and analysis of the recorded neural signals. To ensure their effectiveness, I also verify the performance of these devices through in vivo testing.

Within this project I developed the KiCad ‘cut tracks at line’ plugin which accelerates flex cable (PCB) design in KiCad.

Hybrid Lithography Workflow for Microfluidic Mother Machine Fabrication

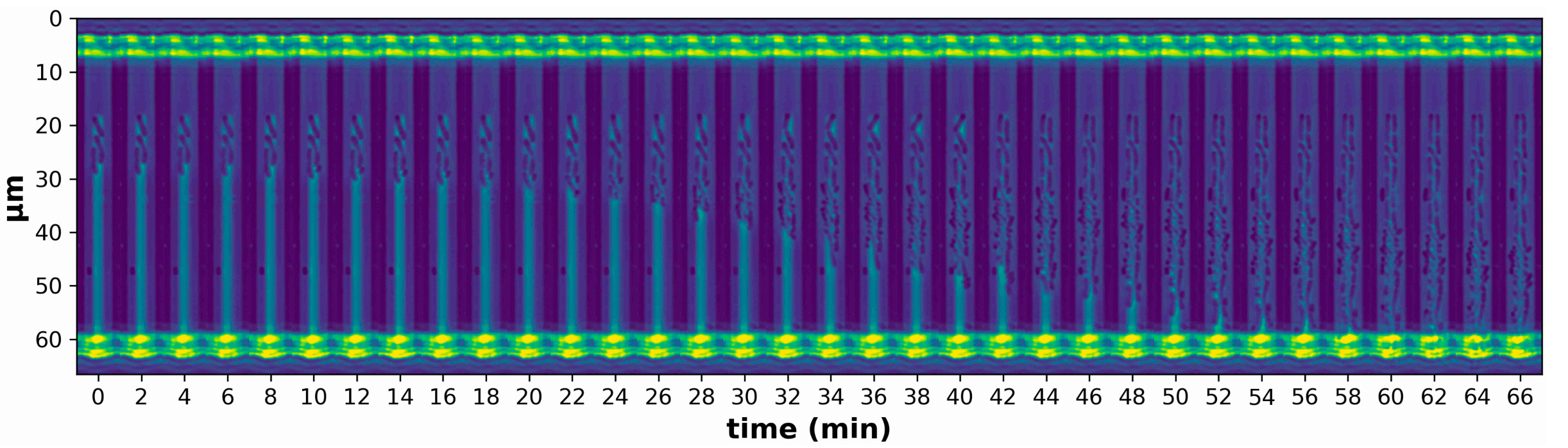

Temporal montage of micrographs of a single mother machine trench (kymograph) showing initial loading and subsequent replication of bacteria. Channel diameter: 5 μm.

In this project, I developed a hybrid lithography workflow for my collaborator Dr Camillo Moschner to fabricate mother machines for spatially confining bacteria in a microfluidic chip. Our approach combines conventional photolithography with two-photon direct laser writing (Nanoscribe), which allows the fabrication of three-dimensional channel geometries with sub-micron resolution. The combination of these techniques also allows extremely short design iteration times from channel design in CAD software to in vitro application on the same day.

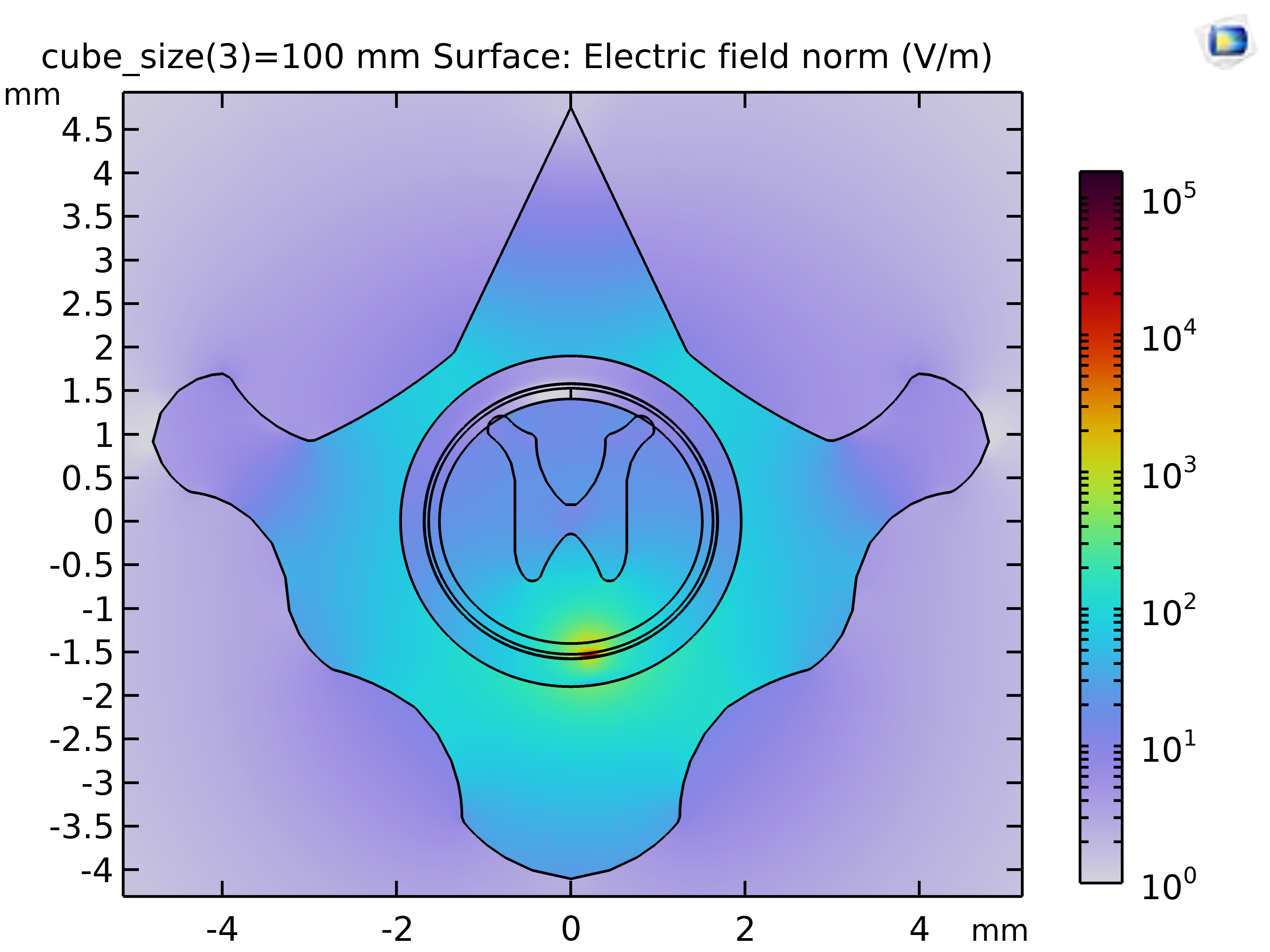

Finite Element Simulation of a Spinal Cord Stimulation Device

In this project, I conducted finite element method simulation using COMSOL Multiphysics to analyse the current distribution in the spinal cord tissue using a flexible electrode array developed by my collaborator Dr Ben Woodington. The model geometry is based on MRI scans of rat T10 vertebrae. This model helped to predict the current distribution and to choose stimulation parameters in a rodent in vivo study. The results of our work are presented here.